Cities

Price

Textile Carts and Equipment

114 Ads Found for

-

Mobiliary Shelf Cabinet KM 127.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Mabilya Shelved Cabinet KM 128.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Mabilya Shelved Cabinet KM 129.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Mabilya Shelved Cabinet KM 130.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Mobiliary Shelf Cabinet KM 131.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

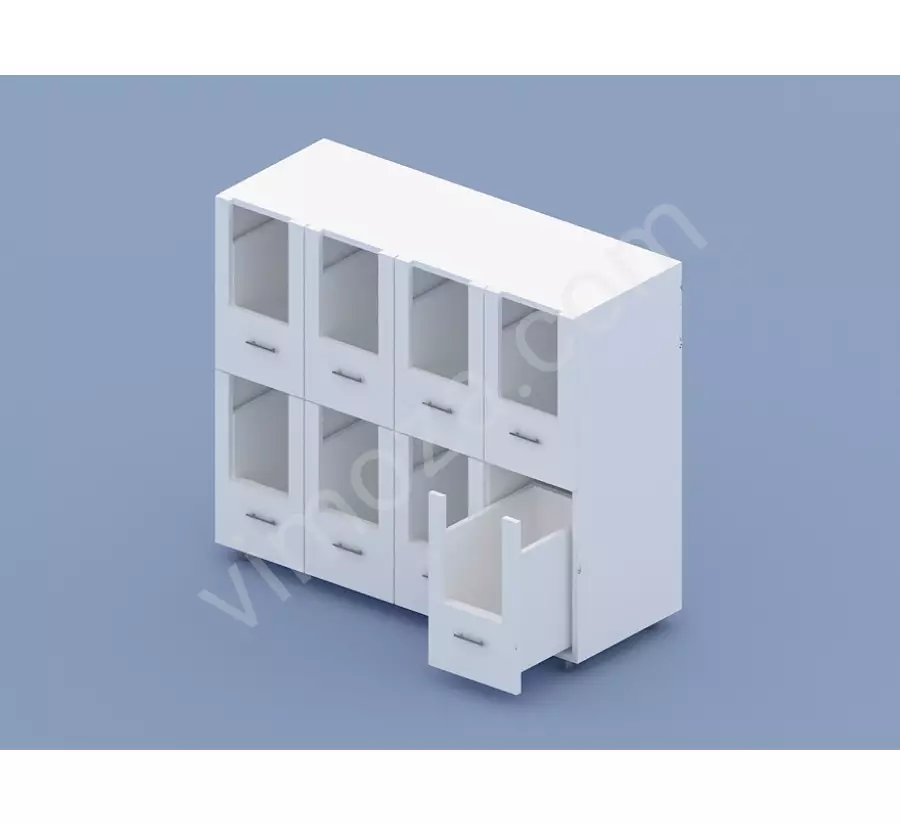

Keson Drawer KM132.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Mobiliary Shelf Cabinet KM 134.

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Mobiliary Shelf Cabinet KM 135

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

Furniture Shelved Cabinet KM 136

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

-

7-Step Ladder KM121

- Kortaş Raf

- Ad Date : 10 Oct 2024

- Address : Türkiye / İstanbul / Bahçelievler

Textile Cars and Equipment

Textile cars and equipment are essential tools used in the textile industry to increase efficiency and optimize production processes. These tools facilitate various operations such as the transportation, processing, and storage of fabrics. In the textile sector, the right choice of equipment can directly affect the quality and speed of production.

Textile cars are generally used for the transportation and storage of fabric rolls. These cars are made from durable materials and can usually be moved easily thanks to their wheeled structures. By accelerating the flow of materials on the production line, textile cars reduce labor costs and make the production process more efficient.

Among textile equipment, there are various devices such as cutting machines, sewing machines, printing machines, and dyeing machines. These machines play a critical role at every stage from the design to the production of textile products. Cutting machines ensure that fabrics are cut to the desired dimensions and shapes, while sewing machines enable the assembly of fabric pieces and the creation of the final product.

Printing machines make it possible to apply patterns and motifs onto fabric. These machines add aesthetic value to textile products while also allowing brands to express themselves. Dyeing machines, on the other hand, ensure that fabrics are dyed in the desired colors, and the permanence and vibrancy of the colors are of great importance in this process.

The maintenance and regular inspection of textile cars and equipment are necessary for long-lasting and trouble-free use. Regular cleaning and maintenance of the equipment prevent disruptions in the production process and enhance workplace safety. Additionally, keeping up with technological advancements and integrating new equipment can increase production capacity and quality.

In conclusion, textile cars and equipment form the backbone of the textile industry. The correct selection and use of equipment optimize production processes, reduce costs, and improve product quality. To remain competitive in the textile sector, it is crucial to use these tools effectively and continuously follow innovations.