Cities

Price

Kuyum Makinaları

87 Ads Found for

-

Mini Induction Melting Furnace

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Hydraulic Press 5 Ton

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

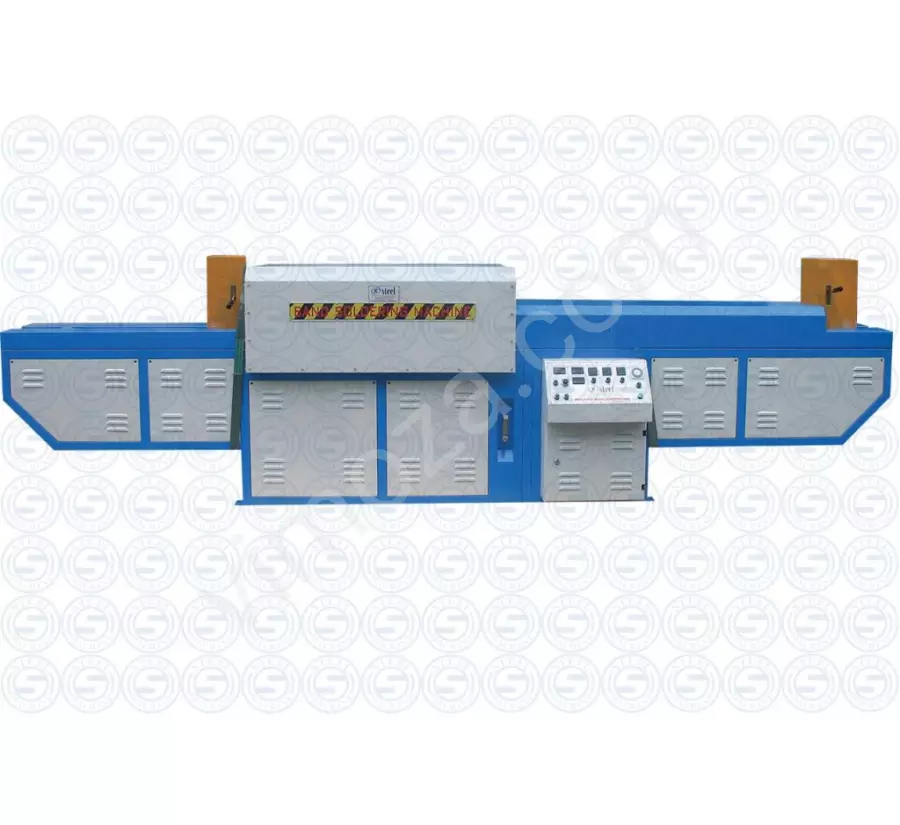

Polishing Machine Large Size

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Ball Pen Throwing Machine

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Ballpoint Pen Selling Machine

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Pencil Throwing Machine for Telepipe

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Melting Furnace

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Drilling Machine

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Electrozone Machine

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

-

Lap Machine

- Steel Kalıp Makina

- Ad Date : 04 Oct 2024

- Address : Türkiye / İstanbul / Başakşehir

Kuyum Makinaları: Değerli Takı Üretiminin Kalbi

Kuyum makinaları, mücevherat sektöründe vazgeçilmez bir rol oynar. Bu makineler, altın, gümüş ve diğer değerli metallerin işlenmesinde kullanılır ve takı üretim sürecinin her aşamasında kritik bir öneme sahiptir. Kuyumculuk sanatı, tarih boyunca estetik ve zanaatkarlığın birleşimi olarak kabul edilmiştir. Bu sanatın modern dünyadaki temsilcileri olan kuyum makinaları, üretim süreçlerini hızlandırırken aynı zamanda kaliteyi de artırır.

Kuyum Makinalarının Çeşitleri

Kuyum makinaları, farklı işlevlere sahip çeşitli türlerde gelir. Döküm makinaları, metallerin eritilerek kalıplara dökülmesini sağlar. Kesim ve şekillendirme makinaları, metallerin istenilen forma getirilmesine yardımcı olur. Parlatma ve cilalama makinaları ise takıların son halini almasına ve parlamasına olanak tanır. Her bir makine türü, kuyumculuk sürecinin belirli bir aşamasında kullanılır ve bu aşamaların her biri, nihai ürünün kalitesini doğrudan etkiler.

Kuyum Makinalarının Avantajları

Kuyum makinaları, el işçiliğine kıyasla birçok avantaj sunar. Öncelikle, üretim sürecini hızlandırarak daha kısa sürede daha fazla ürün elde edilmesini sağlar. Ayrıca, makineler sayesinde hata payı azalır ve her ürünün aynı kalitede olması garanti edilir. Bu durum, özellikle seri üretim yapan firmalar için büyük bir avantajdır. Bunun yanı sıra, makineler sayesinde daha karmaşık tasarımlar kolaylıkla hayata geçirilebilir.

Teknolojinin Kuyum Makinalarına Etkisi

Gelişen teknoloji, kuyum makinalarının da evrim geçirmesine neden olmuştur. Günümüzde, 3D yazıcılar ve CNC makineleri gibi ileri teknoloji ürünleri, kuyumculuk sektöründe devrim yaratmıştır. Bu teknolojiler, tasarım aşamasından üretime kadar her adımda daha fazla esneklik ve hassasiyet sunar. Özellikle 3D yazıcılar, karmaşık ve detaylı tasarımların hızlı bir şekilde prototiplenmesine olanak tanır.

Kuyum Makinalarının Geleceği

Kuyum makinalarının geleceği, teknolojik gelişmelerle şekillenmeye devam edecektir. Otomasyon ve yapay zeka entegrasyonu, üretim süreçlerini daha da optimize edecek ve insan müdahalesini minimuma indirecektir. Bu durum, hem maliyetleri düşürecek hem de üretim kapasitesini artıracaktır. Ayrıca, çevre dostu üretim tekniklerinin benimsenmesiyle, kuyum makinaları daha sürdürülebilir bir geleceğe katkı sağlayacaktır.

Sonuç olarak, kuyum makinaları, mücevherat sektörünün bel kemiğini oluşturur. Bu makineler, hem üretim süreçlerini hızlandırır hem de kaliteyi artırır. Teknolojinin de desteğiyle, kuyum makinaları gelecekte daha da gelişecek ve sektöre yön vermeye devam edecektir.